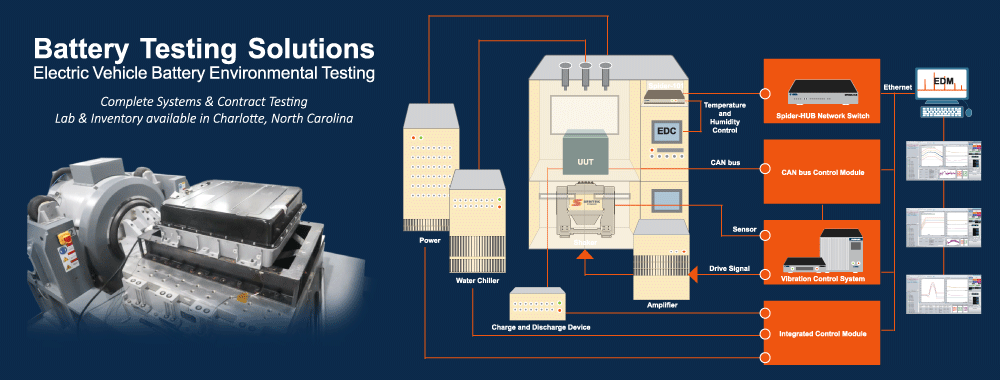

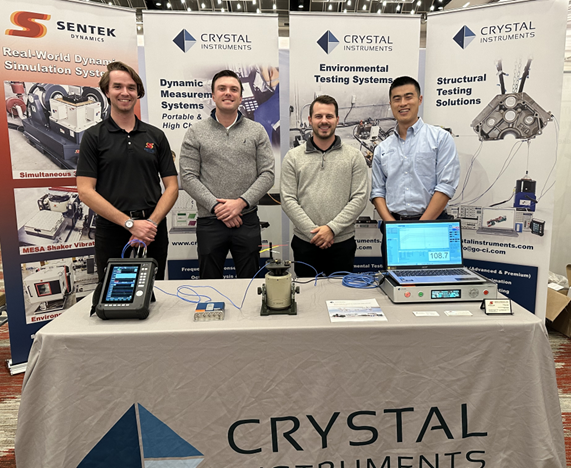

Complete Solutions for Demanding Environmental Test Requirements

Located in the center of Silicon Valley, Sentek Dynamics offers a comprehensive product line with complete environmental solutions for today's demanding test requirements. An additional facility located on the east coast in North Carolina will soon offer systems that are tested and assembled in the USA. Watch the Introduction to Sentek Dynamics video. View vibration testing systems available for immediate shipment.

PRODUCT OVERVIEW

ASSEMBLED IN USA

Tested & Assembled in the USA

Sentek Dynamics is in the process of establishing a local team to begin product assembly at our Kannapolis, North Carolina facility. Testing systems will be assembled from globally sourced parts and tested at our North Carolina location before shipping.

Watch Sentek Dynamics Introduction