(Page 1)

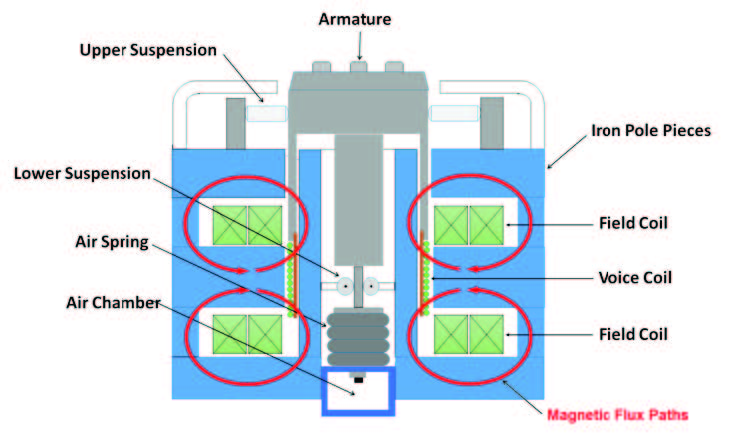

As a shaker becomes larger, it becomes less-and-less feasible to use permanent magnets to derive the fixed reference flux. Environmental test shakers derive their magnetic field from electromagnetic coils excited by a fixed DC current. As in permanent magnet designs, these axially-wound coils act in consort with soft iron pole pieces to focus a radial flux field through the armature’s voice coil, which is driven by a variable current to induce vibratory motion. A pair of axial coils is used to minimize the magnetic leakage near the load table (top of armature). By using two additive flux paths, the strong driving radial field (and the flux gap in which the voice coil moves) are positioned lower within the iron body of the shaker. This greatly reduces the stray magnetic flux passed through the DUT and control instrumentation.

These shakers are designed to vibrate small to large and heavy objects. For this reason, their suspensions incorporate an internal load support system (ILS) using an air-spring to support the weight of the device under test while the armature remains centered in its stroke range. These bladder-like pneumatic springs are filled with shop air. A pressure between 0.2 and 0.6 MPa (29 to 87 PSI) will maintain the armature in the center of its stroke range for any tested mass up to the specified maximum static payload of the system. On any Sentek Dynamics shaker, shop air may be added manually through a through a Schrader ® valve while monitoring the armature position against a mid-position gauge. With the optional automatic armature centering (AAC) module the armature mid-point position is maintained automatically. An over-travel interlock prevents the armature from moving outside of its designed stroke range by interrupting the drive signal from the amplifier until the necessary corrections are made.

For shakers providing over 3kN (660 lb) force, the AAC option performs two centering functions. Static centering automates the pressure control of the ILS; change the static payload on the load table and the ILS valves more or less air into the air chamber connected to the air-spring, changing the internal pressure to hold the armature’s vertical position fixed. Dynamic centering provides “fine tuning” of the armature’s center position (in response to temperature change, for example) while a test is running. This is accomplished by adding a DC bias to the voice coil signal. The AAC option is particularly desirable in operations where items of significantly different weight are tested frequently.

The ILS acts like a soft mechanical spring with a preload applied at its reaction end to balance the weight of the DUT. The required operating pressure is proportional to the weight of the DUT (and fixtures) being tested. The stiffness of the air-spring is also directly proportional to the spring’s internal pressure and inversely proportional to its internal volume. Hence, the natural frequency of the loaded armature-on-suspension is constant, regardless of the attached payload. The extra volume of the air chamber connected to the air spring softens the resulting spring rate resulting in a lower table resonance frequency and expanding the usable frequency range of the shaker.

While flexures are no longer needed to support the weight of the bare armature, structure is required to hold it concentric with the pole pieces forming the flux gap. This is accomplished by using suspension elements above and below the voice coil. Depending on the stroke (displacement) of the shaker the armature is centered with elastomeric elements or with metallic rolling contact guides. The lower-suspension surrounds a square-post attached to the armature with four elastomeric rollers. All elements of these suspension systems are adjustable for wear and can be readily replaced.

Schematic representation of an electromagnetic shaker emphasizing the magnetic circuit and the internal load support (ILS) suspension. Two flux paths sum at the voice coil location, reducing flux leakage near the DUT. The pneumatic spring of the ILS system provides a low stiffness with zero static deflection. A guidance system below the voice coil prevents an off-center DUT from rocking the armature.

Above - “Roller-truss” upper suspension used in shakers with up to 51 mm (2 in) stroke has four elastomeric elements

Above - Rolling link “dog bone” used in longer stroke machines is entirely metallic.

Left - Lower suspension square guidance post sitting on air-spring over air chamber and base attachment plate. The post is held to the armature by a screw. Right - Lower guide rollers that surround the guidance post are retained by a ring that is secured to the inner pole piece.