Electric Vehicle Battery Testing Systems

Sentek Dynamics provides complete systems for electric battery durability testing. Contract testing services are also available from the Sentek Dynamics Lab in Charlotte, North Carolina. Contact the Sentek Dynamics team to learn more.

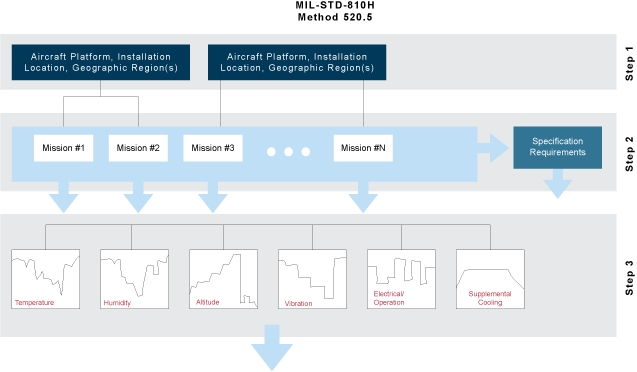

Electric Vehicle Battery Testing StandardsPerform electric vehicle battery abuse & durability tests according to MIL-STD, SAE, UL, ISO, & more. Contact the Sentek Dynamics team to set up testing projects. Dedicated application engineers are available to assist projects from 6:00 AM to 6:00 PM Pacific time. |

|

|

|

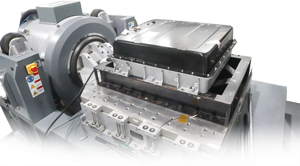

Single Axis Vibration Testing OptionsElectric battery vibration testing is required to verify the battery's durability against harsh conditions resulting from shipping and everyday usage to ensure their safe operation. Environmental hazards can range from extreme temperatures to repeated shocks and vibrations resulting from transportation. |

|

|---|---|

|

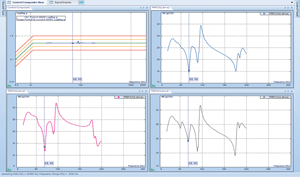

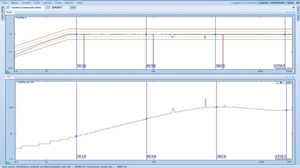

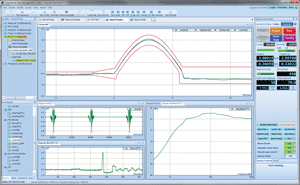

Random Vibration Testing - Random is the most popular type of excitation. Gaussian or non-Gaussian random signals are generated by the Spider controller to create a broadband excitation to the shaker. Feedback control signal meets most stringent requirements defined by aerospace or military testing standards. Input channels can be set as control, monitor, or limit. |

|

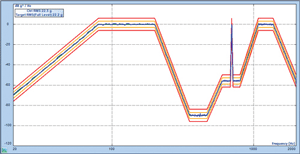

Swept Sine Vibration Testing - Swept Sine Vibration Control provides precise real-time multi-channel control. It provides a spectrally pure and undistorted sine wave and a control dynamic range of up to 100 dB. As many as 512 channels can be enabled for control, notching, or monitoring, while supporting time-data recording. |

|

Multi Sine Vibration Testing - Multi-Sine control enables multiple sine tones sweeping simultaneously and ensures that multiple resonant frequencies of the structure can be excited. With multiple sine tone excitation, the required time duration of sine testing can be reduced significantly. |

|

Classical Shock Control - Classical Shock Control provides precise, real-time, multi-channel control and analysis of a transient motion in the time domain. Classical pulse shapes include half-sine, haversine, terminal- peak sawtooth, initial-peak saw tooth, triangle, rectangle, and trapezoid. Applicable Test Standards include MIL-STD-810F/G/H, MIL-STD-202F, ISO 9568 and IEC 60068 (plus user-defined specifications). |

|

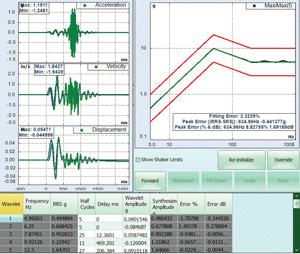

Shock Response Spectrum (SRS) Synthesis & Control - The SRS synthesis and control package provides the means to control the measured SRS of the DUT to match a target SRS, the Required Response Spectrum (RRS). The necessary drive time history is synthesized from damped-sine or sine-beat wavelets. Damped Sine Parameters include frequency, amplitude, critical damping factor, and delay. Waveforms may be automatically synthesized from a user-specified SRS reference profile. |

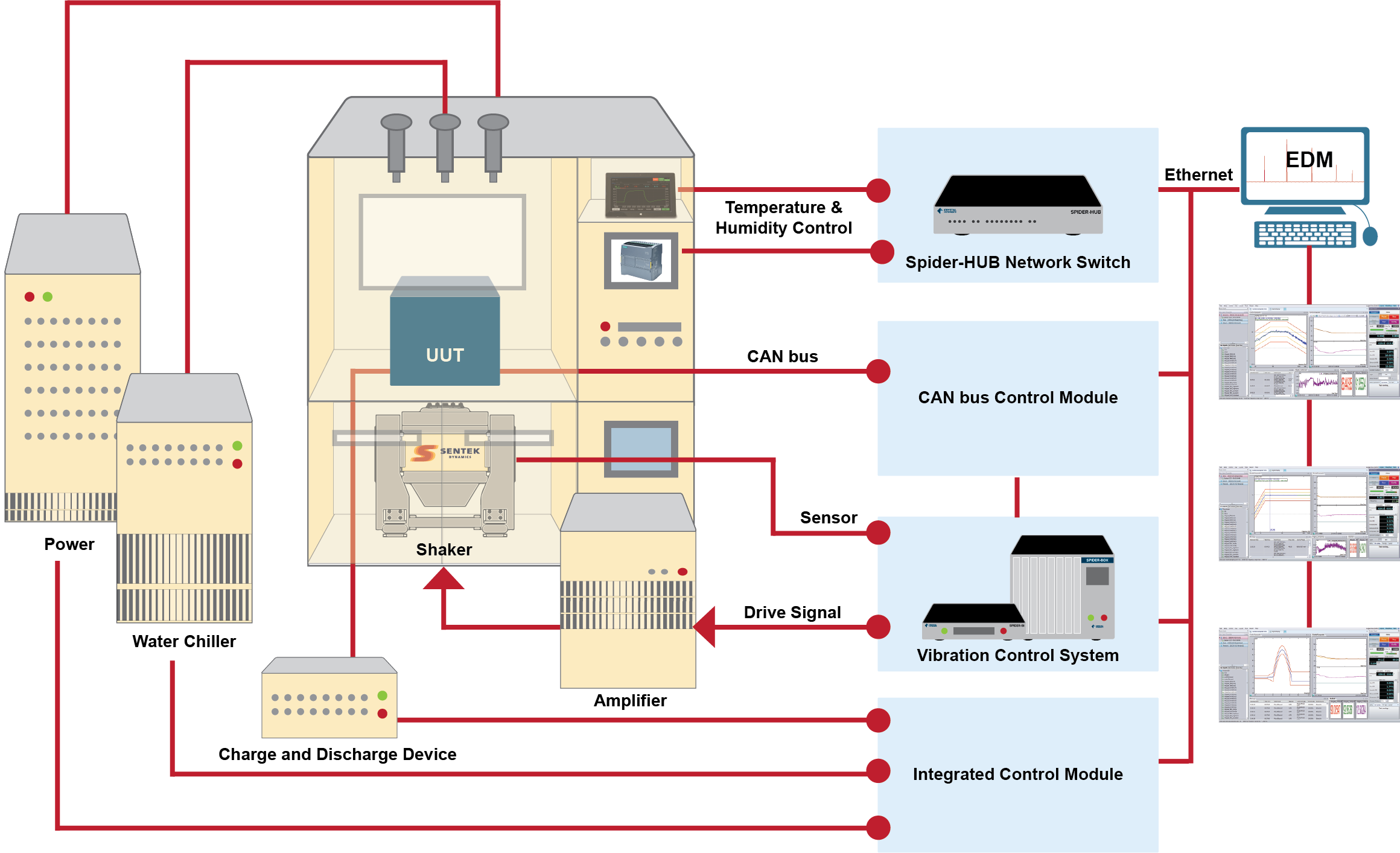

THV Environmental Test SystemsThe industry trend demands environmental testing conducted in fully integrated environments. Various physical parameters, including vibration (acceleration, velocity and displacement), temperature, humidity, pressure, torque, and electrical signals such as those from CAN bus should be monitored and controlled by one system. |

|

|

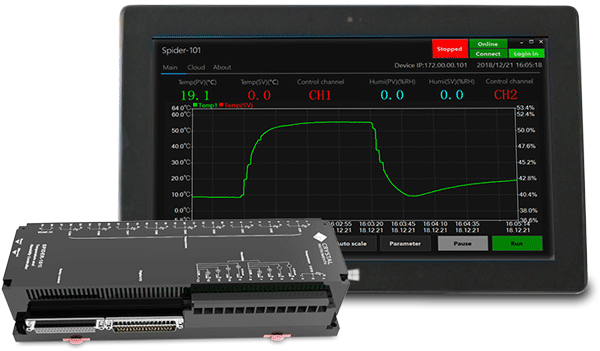

The Spider-101i is designed to perform tests subjecting the DUT to simultaneous temperature cycling and variable humidity. The Spider-101i controls both temperature and humidity in a chamber system, which includes external heating/cooling and humidification/dehumidification systems. PTP time synchronization technology and Ethernet connectivity allows all Spider hardware to be accessed and configured as one integrated system. When vibration control is required along with temperature and humidity control, users are able to conveniently access the parameter and schedule setup between all combined physical quantities from one fully integrated user interface. If a THV (temperature, humidity, vibration) system (chamber + shaker) is equipped with a Spider-101i controller, the controller software allows the addition of a Spider vibration controller and operates the two systems as one while providing an integrated user interface. Users can execute vibration tests such as Random, Sine, Shock, SoR, RoR, and other types together with various cycle settings of temperature and humidity.

|

Contract Testing from Charlotte, North CarolinaOur in-house team provides expert assistance for battery testing projects and are available to provide affordable contract testing services. |

|

Testing services include but are not limited to the following list.

|

|

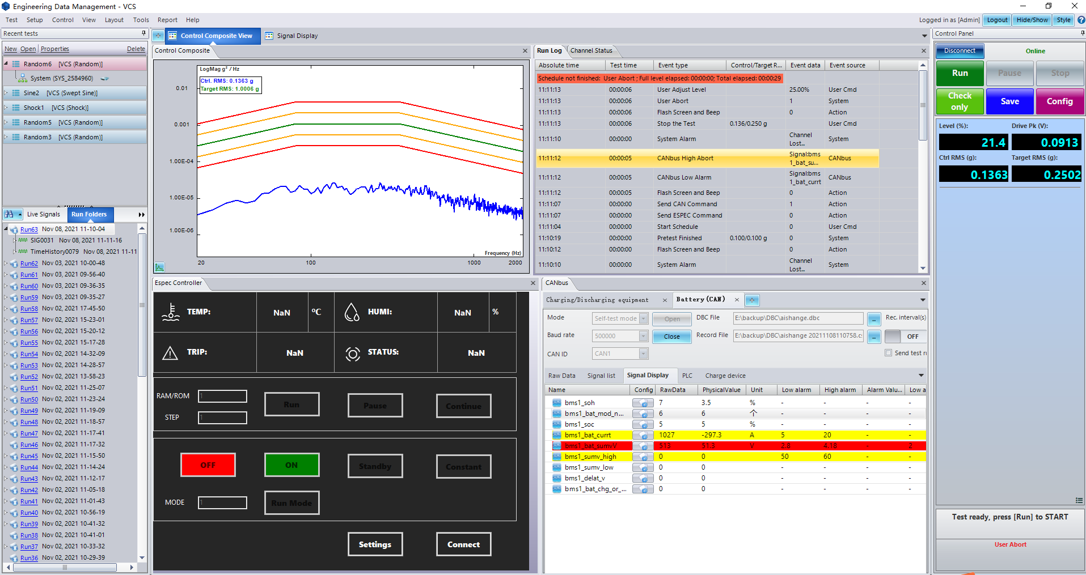

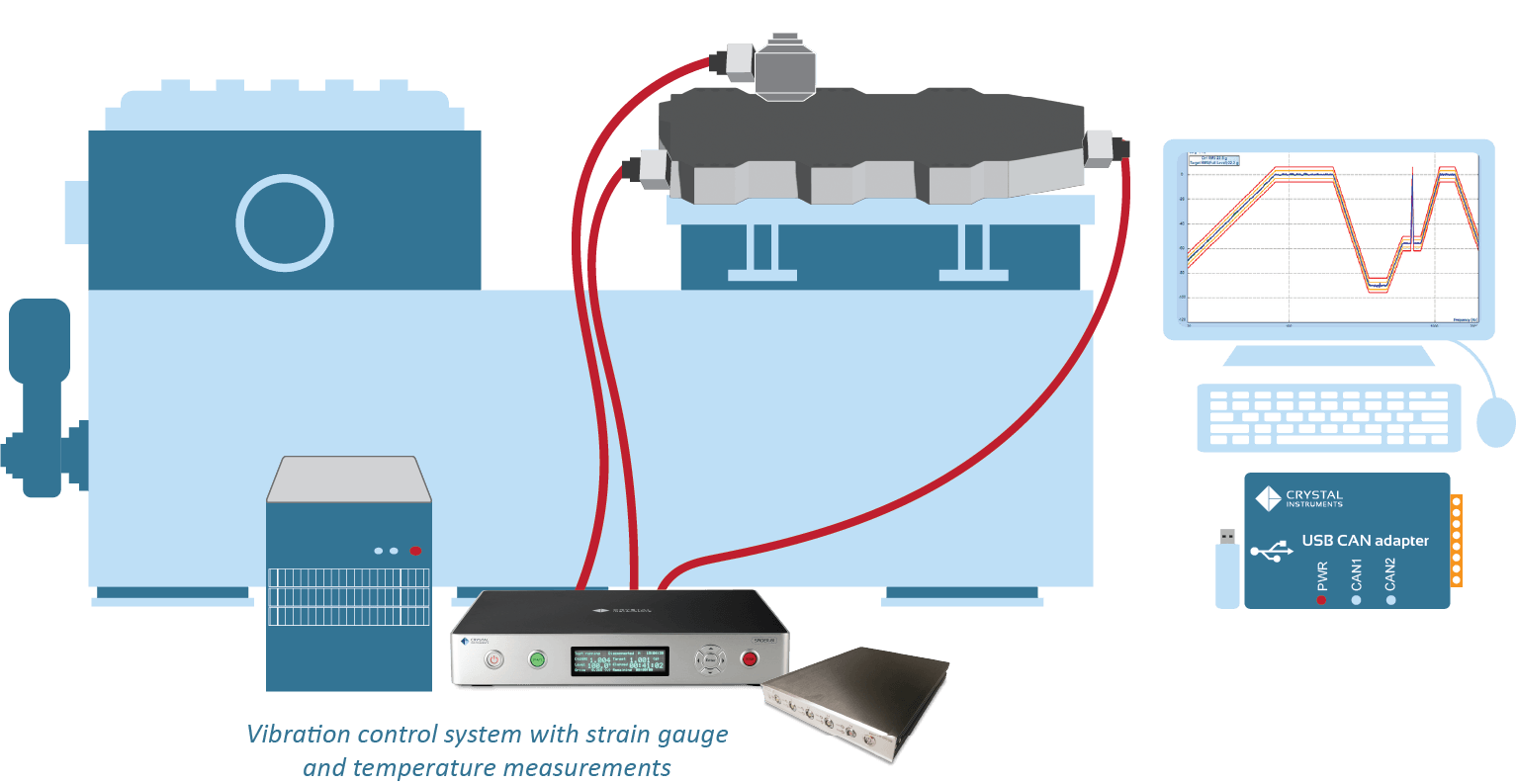

Combine Electric Battery Environmental Testing with CAN bus SupportCAN bus alarm and abort rules can be configured during a vibration test with a customer’s DBC file and a custom-built Crystal Instruments USB CAN adapter. For example, a user running vibration tests on an EV battery can configure the software to monitor the battery’s temperature and stop or pause the test in response to the temperature matching or exceeding a particular value. |

|

|

The THV system software supports the custom-built Crystal Instruments USB CAN adapter as well as the PCAN-USB adapter developed by Peak Systems. While performing vibration or THV (temperature/humidity/vibration) tests on a battery pack, the accelerometers, temperature, and humidity sensors can measure the external environment of the battery pack. The Battery Management System (BMS) monitors the internal battery pack status and communicates with external components using CAN bus. The integrated CAN bus support allows EDM to monitor the internal and external status of a battery pack and take actions according to pre-defined conditions. Supports multiple CAN Bus channels and records data simultaneously to a solid-state drive. Expand data storage to 2 TB with the addition of a Spider-NAS. |

EDM Cloud Online Status MonitoringProvided for users to monitor the status of vibration tests across multiple Spider controllers. Allows access to multiple users according to customized account privileges to view data and status of Spider systems. Lab administrators can simultaneously monitor multiple tests from anywhere in the world using EDM Cloud. Supports EDM Vibration Testing and EDC Temperature/Humidity Testing. |

|

|

EDM Cloud can also be deployed on local servers within an organization’s network. This allows an organization to limit the scope of information exchange and data sharing to users within their network to ensure data security. This feature is useful for monitoring the progress and status of environmental tests with classified information. Visit https://cloud.go-ci.com/ to register and log on. EDM Cloud allows users to:

|

Data Acquisition During Environmental Battery TestingRecord CAN bus data, peak CAN data, time data, dynamic measurements (APS, FRF, frequency domain data, etc.), cycling data logging (voltage, current, battery, etc.) |

|

|

Combine a Spider vibration controller with a Spider-80SG unit to acquire data from a strain gage or a wide range of sensors. With the help of precision excitation voltage, the Spider-80SG/SGi can support strain gage based sensors, MEMS sensors, IEPE and DC sensors (to name a few) thus expanding the scope of the Spider-80Xi hardware platform to support the synchronized acquisition of a wide range of measurement quantities including Force, Torque, Pressure, Acceleration, Velocity and Displacement. It can be used for strain measurement and many other types of sensors that requires external power. The Spider hardware platforms (including the Spider-80X/Xi and the Spider-80SG/SGi) share the flexibility of scaling up in channel count and functionality. The Spider-80SG/SGi can combine with any Spider-80Xi device to create a high channel count system with up to 512 channels to perform data acquisition during vibration tests. A dedicated massive storage hard disk (a 250 GB solid-state drive) allows the time signals of all input channels to record at up to 256 kHz/channel. Accurate time synchronization results in excellent phase match in the frequency domain between all channels, either on the same Spider front-end or across different front-ends. |