(Page 2)

Temperature

Temperature regulation is established via temperature cooling sub-systems and a heating system. For cooling, mechanical cascade vapor-compression refrigeration and liquid nitrogen cooling are utilized. Based on the temperature ramp rate, methods of cooling can utilize the cascade vapor-compression refrigeration system or liquid nitrogen system. The heating system consists of high-power resistance wire heating. These methods are applied to an optimized high-volume airflow system for controllability within the chamber to minimize temperature gradients across the device under test. A benefit of using Liquid Nitrogen & Compressor cooling systems combined with better airflow, temperature change rates are accelerated while maintaining excellent temperature control.

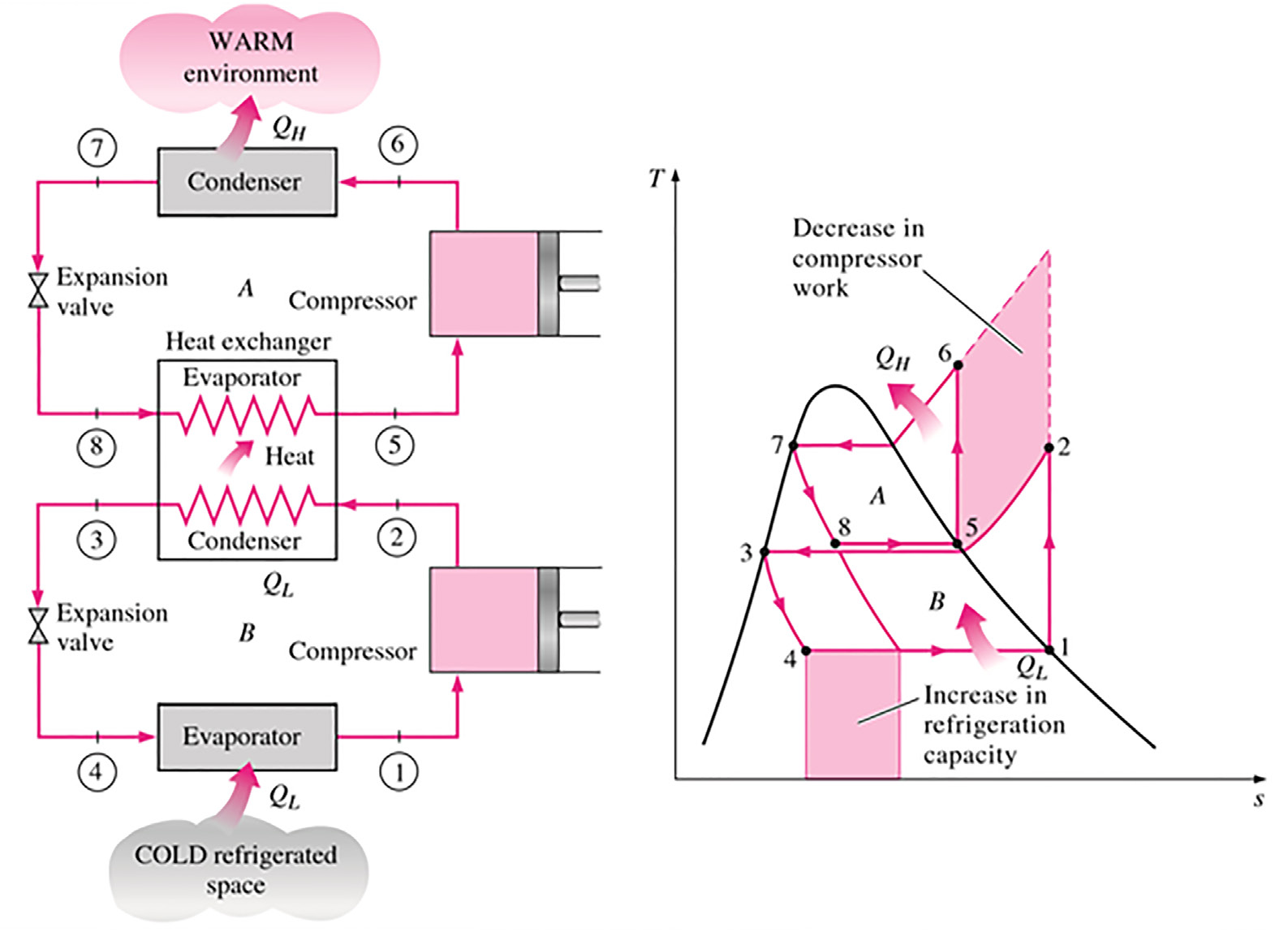

| Cascade Refrigeration The THV chamber incorporates a two-stage cascade refrigeration cycle. The two cycles are connected through the heat exchanger which serves as the evaporator for the topping cycle and the condenser for the bottoming cycle. Cascade refrigeration allows for increased refrigeration capacity with reduction in individual compressor work to improve the coefficient of performance (COP) of the system. |

Liquid Nitrogen Cooling Liquid Nitrogen Cooling Liquid nitrogen cooling is used to produce extremely low temperatures. Incorporated to work in conjunction with the cascade refrigeration system, liquid nitrogen cooling assists in providing enhanced chamber temperature performance. |

Cooling Unit THV chamber cooling is highly efficient and reliable due to its advanced design and application of cascade refrigeration along with liquid nitrogen cooling. Features include low-noise compressors, environmentally friendly refrigerants (R404a, R23), nitrogen protected oxidation-free welding, and pneumatic, hydraulic and evaporation temperature adjustment for extended life span. |

|---|

Humidification

Humidification is achieved by injecting steam into the chamber. This steam is generated when the is heated by a wire heating furnace. A water level interlock and automatic water control delivery system is also part of the humidification sub-system. Dehumidification results from application of the desiccation principle, where air is cooled to a temperature below the dew point so that the moisture content is greater than the saturated water vapor condensation precipitation, thus lowering the humidity. Water purifier is listed as an option which softens and purifies water for the humidification and dehumidification processes.

(Click to enlarge.)