Manufacturing plants often require controlled vibrations on various parts of the plant to run for several hours, days, or even weeks at a time. In some cases, continuous operation is required.

At these facilities, the affordable down time is limited to a few hours in a week. The continuous controlling and monitoring of independently running systems is another significant challenge. Monitoring each controller on a separate PC would require an unreasonable number of PCs to monitor. The necessity to run different types of controlled vibrations on these machines makes it impossible to use MIMO (Multi-Input Multi-Output) control. Also, when used with a single PC with MIMO control, memory and computational resources of the PC would become unreasonably high when the number of shakers needed to be controlled grows larger than 10.

Crystal Instruments has designed a way to overcome these limitations, providing a solution for controlling and monitoring several dozen shakers simultaneously through one PC.

The Spider product line is designed to run independently in Black Box mode (operating without a PC). All computations are performed on a powerful digital signal processor residing inside the Spider front-end. With a high on-board memory, the Spider does not require a PC for control. A PC is required only for an initial setup of the test parameters on each of the Spiders. Multiple such combinations of parameters (each one is called a test), can be uploaded to each Spider memory. Specific tests can then be selected through the front panel of the Spider-81 or through a special software interface designed by Crystal Instruments.

Once selected, the test with desired parameters will continuously control the shakers for the user specified duration of time (hours, days, weeks or even months). Each Spider will be controlling one shaker and every Spider can have an entirely different set of parameters.

All the Spiders can then be simultaneously monitored using a special software API developed by the Crystal Instruments. This easy-to-use lightweight tool takes much less memory on the PC and avoids any issues that cause the PC to malfunction, even after several weeks of continuous operation.

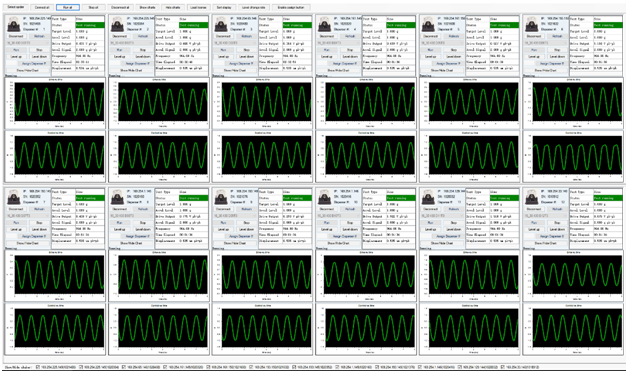

The API can be customized to display up to 27 shaker systems simultaneously on a single screen. Test status, drive output, control input or any other live signal can be customized for the display.

Options to start and stop tests, switch tests, and fine tune the control amplitude are some of the key functions that can be controlled for each Spider using the API.

Picture 1: Crystal Instruments’ API monitoring 12 shakers running a Sine test.

Since the Spider product line is designed to operate without a PC, the Spiders will continue to accurately control the shakers even when a PC or Windows operating system should shut off for any reason.

When the PC is backed up, the monitoring will continue without affecting the shakers in any way. The easy- to-use hardware buttons can also be used to Start and Stop the tests or switch between different tests, should the need arise.

The DC-powered Spider product line consumes extremely small amounts of power and thus emits a negligible amount of heat. This enhances the durability of Spiders to operate even under severe conditions, such as many consecutive months of continuous operation. Unlike the complex operating system of a PC, the Spider firmware (mostly mathematical calculations) is exclusively designed for data acquisition and vibration control. Hence, the possibility of a crash and the requirement to restart the hardware at frequent intervals is completely eliminated.

With these advanced features and robust qualities, Crystal Instruments has been successful in deploying 12 Spider controllers to control 12 shaker systems independently, which are being monitored through one PC from the API. All of the Spider front-ends have been reported to be working continuously without any interruptions for several weeks as of now.