Fatigue Damage Spectrum (FDS) allows users to compare the potential damage caused by different Random profiles, Swept Sine profiles or a combination of both.

The damage caused by vibration can occur in one of the following conditions:

Damage caused by an extreme instantaneous stress on an object

Damage caused by fatigue when a high number of cycles of a certain stress level is applied to the object

FDS represent a spectrum with regard to the fatigue damage on an object.

FDS function makes use of the S-N curve to construct the spectrum. The S-N curve represents the stress applied to a material (S) versus the number of cycles of applied stress (N).

The S-N curve of an aluminum bar is shown below:

The FDS function is capable of providing a way to reduce the testing time by calculating the quickest path to destruction or damage. Testing time is accelerated by concentrating the Random or Swept Sine energy, depending on the FDS calculation, to where it will induce the most fatigue damage.

In short, FDS lets the user understand which profile will cause more damage on the object and use this information along with other parameters such as kurtosis to reduce the testing time.

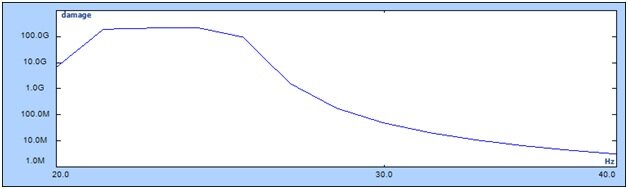

Here is a fatigue damage spectrum of a Sine profile at 4g peak from 20 Hz-40 Hz:

Below is a fatigue damage spectrum of Random profile at the same level with the same peak and frequency range:

As observed by these specific tests, the fatigue damage caused by the Random profile in the higher frequency domain is greater than that of the Sine profile. However, in the lower frequency range, the fatigue damage is similar.

Of course, the results depend on the characteristics of the test object (such as the slope of the S-N curve) and the level and frequency range of the profiles.

This will provide a way to compare and investigate which profile with relatively the same level would be suitable to run for a specific test. In many tests, the goal is to estimate the target life of the object by failing the object. By conducting the FDS analysis, the time of an extended test can be reduced significantly (for example, a 400-hour test to a 40-hour test) to achieve the same goal, which is failure.

In the case of an expensive and complex test object, such as a satellite, complete destruction is not desired. Accordingly, using FDS analysis, the duration and strength of the stress can be scaled back to observe possible loose parts during long-run vibration tests.